D. CASING AND SHELL

REPAIRS

- 1. Machine eroded seal fits; weld,

or install inserts and remachine to proper size.

- 2. Replace inserted seal strips with

new parts and machine for correct clearance.

- of-roundness, distortion by welding

and/or machining.

- 4. Repair keyways, bolting holes, nozzle

faces and other critical surfaces.

- 5. Weld repair turbine case and stress

relief

- Machine gibs and keys for proper

nozzle alignment

- Weld repair inlet pipes

- Stress relief anlet pipes

- Straightena dn align inlets

- Fixture to aling inlets during stress

relief

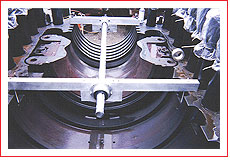

- Machine bell seal fits

- Machine new threads for bell seal nut

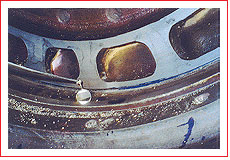

- Grind out and clear all cracks in

steam chest

- Weld repair to fill ground ou areas

- Stress relief after weld repairs

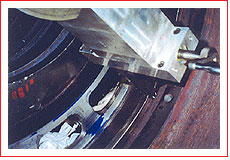

- Machine nozzle sealing face to maintain

original axial location

- Machine radial nozzle fit

- Replace seals and machine to proper

diameter and restore seal clearance to factory specifiactions

|