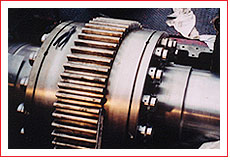

A. TURBINE ROTOR INSPECTION

AND REPAIRS

- 1. Runout and dimensional checks.

- 2. Grind journals, thrust runners or seal

areas.

- 3. Machine eroded or damaged areas; offset

machine bowed rotors.

- 4. Machine for modification and/or clearance

specs.

- 5. Remove wheels and other shrunk on parts

for repair.

- 6. Line bore coupling bolt holes and machine

rabbet fits.

- 7. Machine/grind coupling bolts for proper

fit.

- 8. Balance check and weight correction.

- Machine coupling bolt holes to meet

specification for straightness and roundness.

- Machine coupling bolt for proper

clearance and fit.

|